产品详情

当前位置:

首页>

产品详情

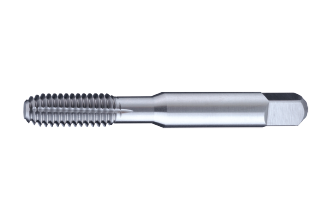

#5-Thread Forming Tap

- 产品详情

These taps have no flutes except as optionally designed with one or more lubrication grooves. The thread form is lobed so there is a finite number of points contacting the work. This tap does not cut metal, so it is ‘chipless’, and consequently will not cause a chip problem. The tool forms the thread by extrusion, thus thread size

can be closely maintained. The fluteless design allows high quality threads, faster tapping speeds, higher production, and generates no chips which simplifies tapping of blind bottoming holes (threads can be formed the full depth of the hole).

下一页